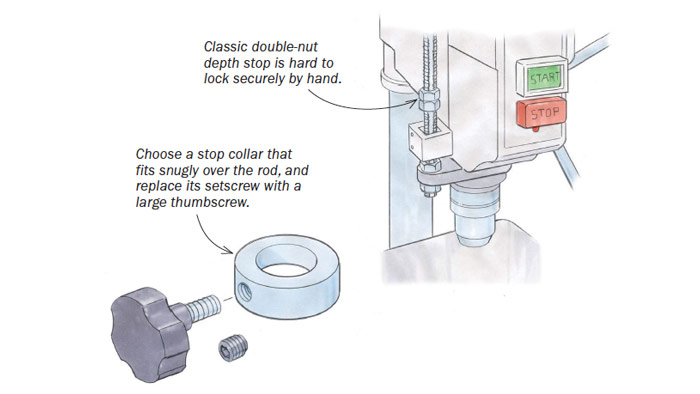

I’ve always been frustrated with the depth stop on my old-school drill press. The trouble is that I can’t twist the two lock nuts firmly enough together by hand, so they tend to shift when the machine is running. Here’s how I solved the problem. First, I removed the threaded rod and filed a flat along one side of it. (You don’t have to file to the bottom of the threads.) Some threaded depth rods already have a flat milled on them, so the filing step might not be necessary. Next, I found a stop collar—the kind used on drill bits—that fit the threaded rod pretty closely, and replaced its little setscrew with a thumbscrew. I slid the stop collar onto the depth-stop post and reinstalled the post in the drill press. Choose a thumbscrew with a handle that’s easy to grip. You’ll be able to apply plenty of clamping force, and your new stop collar won’t slip.

—CHARLES MAK, Calgary, Alta., Canada

Drawings by Dan Thornton

Fine Woodworking Recommended Products

DeWalt 735X Planer

At high speed, the planer works fast and leaves a smooth surface. But the slower, finish speed produces an almost glass-smooth surface. Knife changes are easy.

Rockler Dust Right 1250 CFM

You’ll need help to get this heavy unit onto its bracket, but if you’re looking for a central dust collector that won’t gobble floor space, this may be the unit for you.

Ridgid EB4424 Oscillating Spindle/Belt Sander

With five spindles sized from 1/2 in. to 2 in. and a 4 X 24-in. belt, this sander has become a staple in many a shop Fine Woodworking visits.

Sign up for eletters today and get the latest techniques and how-to from Fine Woodworking, plus special offers.